5 Signs Line Planning and Assortment Planning Don’t Match Up

Line planning and assortment planning are two different but interconnected processes in the operation of getting products to market. To achieve on-target assortments and therefore greater sell-through at full price, they need to be aligned. However, too often line planning and assortment planning are disconnected and held back by a lack of integration between systems, which makes it hard to collaborate and act on accurate, up-to-date data.

What are the signs that line planning is misaligned with assortment planning – and what can you do to fix it?

Line Planning vs Assortment Planning: What’s the Difference?

Mainly involving the merchandising team with some input from design and sourcing teams, line planning is a process that ensures that retailers have the right mix of products to meet customer demand and achieve sales targets. It generates a product assortment plan that outlines the product categories, styles, colors, and sizes that a retailer will offer for a particular season or time .

Before the line planning process takes place, the merchandising team must also prepare the financial strategy otherwise known as the Merchandise Financial Plan (MFP) which will determine the Open-to-Buy (OTB) budget. These various processes, all so crucial to one another, all take place in a myriad of different systems, tools and spreadsheets.

Traditionally, the line planning process takes place across a plethora of notations on foam core boards, notepads, sticky notes, from data compiled from multiple systems such as PLM, ERPs, spreadsheets and BPF tools, and accompanied by physical samples and swatches; all requiring manual management and compilation.

Assortment planning follows on from the product assortment plan and determines the breadth/width of specific products from that collection to offer in alignment with the merchandise financial plan across individual stores and channels. Involving merchandisers, planners and buyers, the purpose of assortment planning is to determine which product mix will maximize sales and profitability by store and/or channel.

The product assortment plan provides a blueprint for assortment planning. Unlike line planning, which is a largely visual process done by hand, the assortment plan is constructed using huge amounts of financial and numerical data pulled from, updated, and re-entered back into a multitude of systems and tools such as spreadsheets, budgeting and planning tools.

It is inevitable that such a crucial process requiring such attention to detail and taking place across multiple locations with different stakeholders will leave misalignment between the three processes, resulting in lost time and information.

5 Signs of Misaligned Merchandise Planning

What are some obvious signs that line planning and assortment planning are not connecting up as well as they should be?

- Merchandisers losing time stuck in spreadsheets. If line planning, MFP and assortment planning are done using different tools, merchandising teams must spend time manually transferring the product assortment plan into the assortment planning tool or spreadsheet and then allocate products to individual stores or channels. A hugely manual and error-prone task.

- Communication breakdowns and delays. If teams involved in line planning and assortment planning don’t have a central reference point for accurate and up-to-date data, they are unable to communicate effectively and make fully informed decisions, leading to errors, rework and delays.

- Poor product performance. Similarly, if sales and forecast data is not aligned with product-related data from a Product Lifecycle Management (PLM) system, retailers may miss opportunities to capitalize on emerging trends or customer preferences. Products perform poorly, leading to revenue losses and even damage to your brand reputation.

- Difficulties optimizing the product mix. No matter how hard your teams work, the product mix never seems to be quite right. Being able to curate assortments by drop, door or channel relies on a vast amount of data from which to analyze, segment and plan. Merchandisers need more advanced tools to achieve their strategic goals and craft more customer-centric offerings where their consumers want them.

- Balancing the assortments. It can be hard to make informed decisions about the product mix and rationalize SKUs when you are looking at rows and rows of numerical data. Images are very important to visualize how products will work together in assortments but aren’t always accessible. Understanding which of your products are performing well early enough to make strategic decisions from spreadsheets and disconnected reports about which colorways or fabrics to drop or carryover is virtually impossible.

Introducing Visual Boards

By aligning these data sets and processes, retailers can ensure that they have accurate information about product demand, capitalize on emerging trends, and maximize profitability. Implementing a collaborative planning process will bridge the gaps between line planning and assortment planning to bring the right products to the right market at the right time, faster.

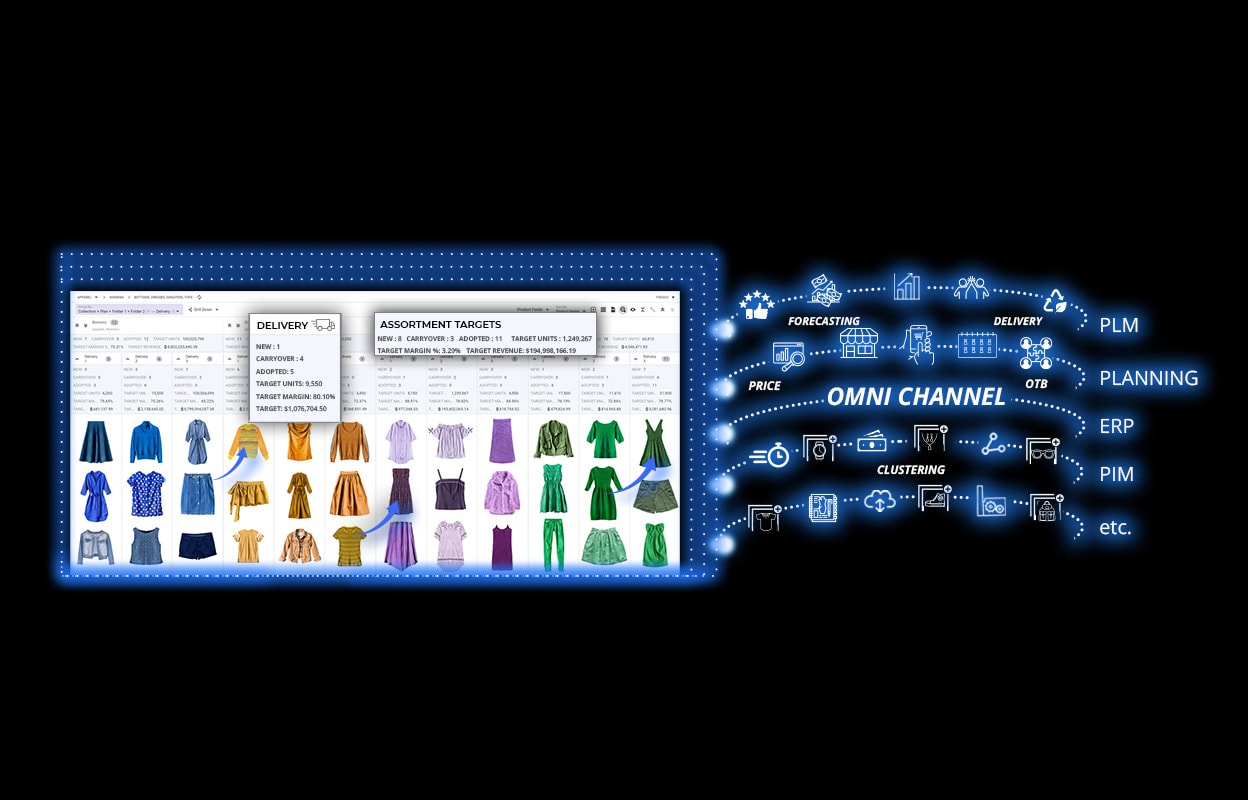

However, this isn’t an easy task. Aligning line planning and assortment planning involves pulling in numerical, textual and visual data from many different systems, from ERP to PLM to retail planning solutions. It can be difficult to achieve remotely using conventional online meeting tools, requiring people to be physically present in the same space.

Thankfully, transformational been developed to address these challenges that enable teams to work better together, either physically or remotely, to collaborate on complex tasks such as aligning line planning and assortment planning. These tools, called Visual Boards, use interfaces that pull in data from many enterprise systems and present it in a visual format.

Merchandising and Design teams are saving weeks’ worth of time with this revolutionary approach to assortment planning, with retailers reporting up to 90% reduction on time spent across the team updating the product assortment plan when using Visual Boards.

Not just a time-saver, brands and retailers are also finding enormous OPEX savings in the millions, from being able to collaborate digitally and remotely to examine line plans and build assortments that are informed by live product data and accurate forecasting.

With simple drag-and-drop functionality, these intuitive tools facilitate what-if scenarios and visual decision-making to build the best assortments possible and ultimately improve sell-through.

Without proper visibility and the ability to collaborate effectively, line plans and assortment plans won’t match up. If you’re seeing signs of misalignment such as wasted time, overstocking and unsuitable product mixes, it’s time to look at how you can make these intertwined processes work better together.